Typical Conditions

Download List

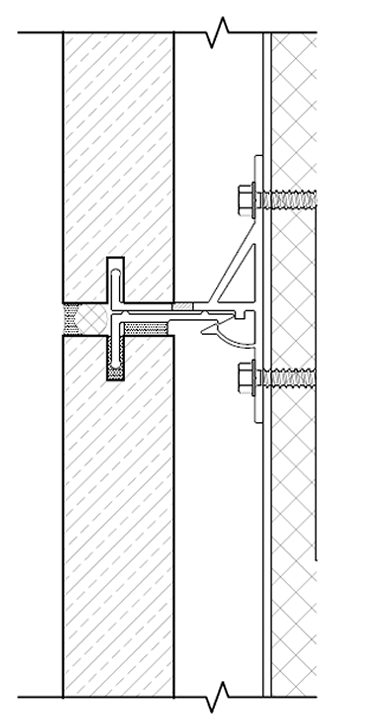

Sealed Joint

Typical Details

Soffit Facia Details

Corners

Windows Doors Details

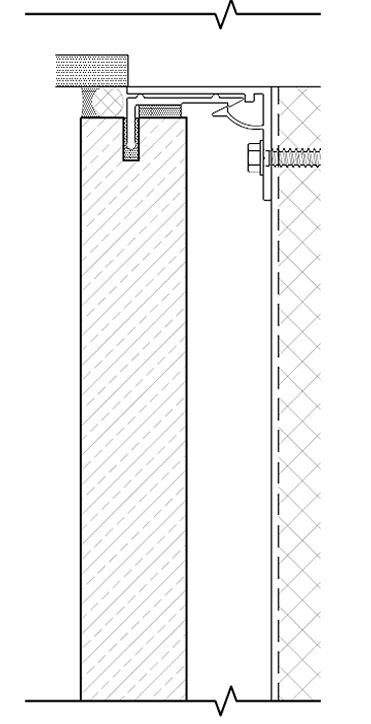

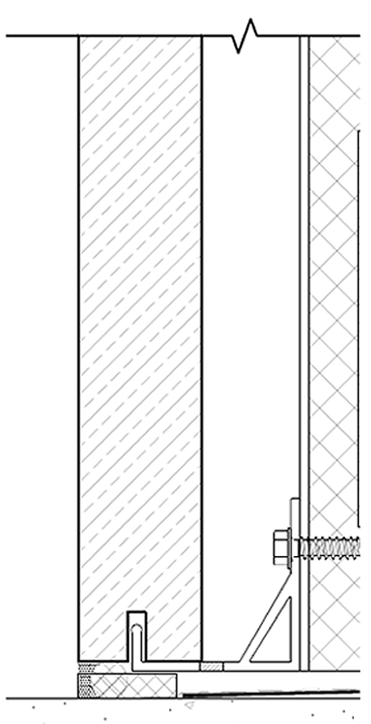

Open Joint

Typical Details

Soffit Facia Details

Corners

Windows Doors Details

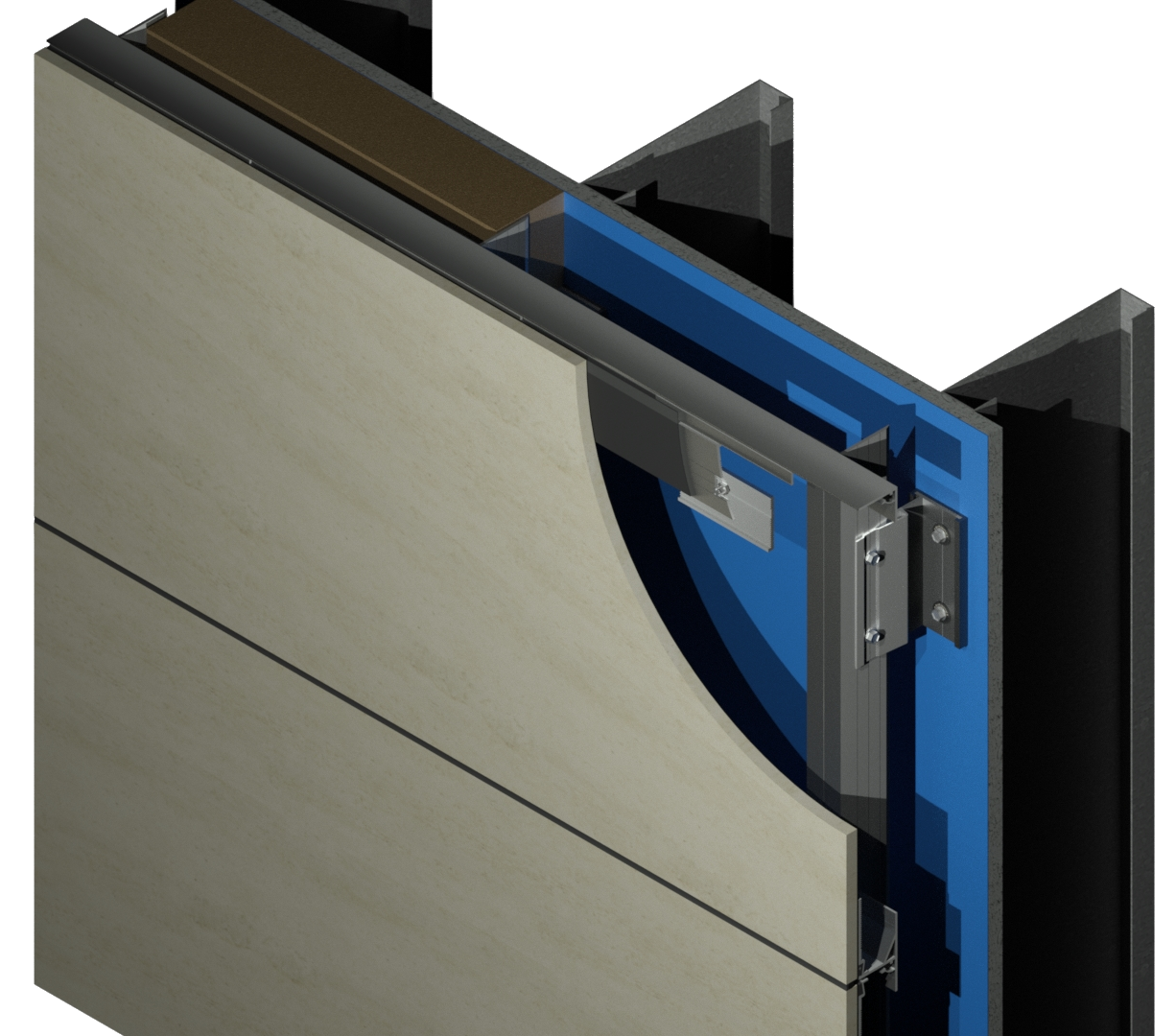

Kerfed Dimension Stone

The patented Gridworx saw kerf system anchors cladding via a continuous kerf located at the top and bottom edge of the cladding panel. This groundbreaking system was the first mechanical attached cladding system to allow for the rotational installation of stone panels. The first to allow for the non-sequential installation of stone, and the first to allow for the removal of damaged or discolored stone without impacting adjacent panels. The patented 2-part system, which fused the traditional T and J anchor with the versatility of a rotational L-bracket, represented the most significant advancement in stone cladding installation in over half a century.

The patented Gridworx saw kerf system anchors cladding via a continuous kerf located at the top and bottom edge of the cladding panel. This groundbreaking system was the first mechanical attached cladding system to allow for the rotational installation of stone panels. The first to allow for the non-sequential installation of stone, and the first to allow for the removal of damaged or discolored stone without impacting adjacent panels. The patented 2-part system, which fused the traditional T and J anchor with the versatility of a rotational L-bracket, represented the most significant advancement in stone cladding installation in over half a century.

All of our anchoring systems are designed to be mounted to the building substrate via our standard Thermally Broken Components providing space in the wall for insulation and adjustability.

This system pairs perfectly with any stone from our collection, cut to architectural specification and delivered to your jobsite.

Continuous support panel dead-load

6005A aluminum alloy T61 temper

75% minimum recycled content

Panel thickness range: 1" - 4"

Kerf Demonstration Video

Thermally Isolated Subframe

A thermal break or thermal barrier is an element of low thermal conductivity placed in an assembly to reduce or prevent the flow of thermal energy between conductive materials.

GRIDWORX strives for the best properties of our materials to provide a thermally efficient, energy-saving product that prevents thermal bridging in structural connections. These thermally broken aspects of our Gridworx mechanical stone cladding system are shown below is a section detail of our ASHRAE 90.1 qualified system including our Gridworx sleeve washer and Thermal Sleeve isolating back plate.

Please note in the section detail the item described as, “1/8” Thermal Break - Thermal Shoe.”This component is best described as a plastic footing that functions as an insulator between our aluminum Z Girt and the substrate (typically Dens Glass).This is an impact resistant, high quality extruded component made from ABS SP-9010 plastic. Further, this material is heat resistant.

The second item is referenced as, “Thermal Isolated Sleeve Washers.”This sleeve washer is made from NORYL Resin SE1GFN PPE+PS blend. 30% Glass reinforced Non-brominated, non-chlorinated FR system.

The second item is referenced as, “Thermal Isolated Sleeve Washers.”This sleeve washer is made from NORYL Resin SE1GFN PPE+PS blend. 30% Glass reinforced Non-brominated, non-chlorinated FR system.Please note the application of this component (drawing above). This washer is designed to first be placed in the pre-drilled hole in the Z Girt.The smaller diameter ring of this component is designed with wings to secure its stability and correct placement in the pre-drilled hole.The sleeve protrusion between this smaller diameter and the larger diameter ring is designed to isolate the steel fastener; keeping it from making contact with the sides of the Z Girt. The larger diameter ring isolates the head of the fastener from contact with the top of the Z Girt.This explanation should make it easier to follow in conjunction with a careful review of the attached section drawing.

This system was designed and approved by SGH Engineering.With a careful analysis, one will note there is no contact between the metal in the wall cavity and that of the steel studs.This is truly a thermally isolated system.

Make good Better

A proposed building design is demonstrated through building energy simulation to use less energy than a baseline building built to ASHRAE 90.1 specifications. All building components must be qualified by individual testing.Gridworx worked closely withSimpson Gumpertz & Heger, an independent engineering firm, in the development of this system. It was deemed to meet or exceed performance standards in Thermal Performance, Air Barrier Performance and Condensation Potential.

GRIDWORX is a ventilated, back drop rainscreen cladding system. It is a comprehensive system unlike none other.Gridworx consists of our patented contemporarily designed aluminum channels, choices of hundreds of natural stone and man made cladding materials, in-house architectural support, independent third party engineering and state of the art sales support.

• Thermally broken Ventilated Backdrop Rainscreen System ( VRS )

• Non combustible construction

• Adjustable for subwall misalignment

• Cladding joints not tied to stud locations – design freedom

• Easy construction, cost effective

• Suitable for weather barrier (as required by ASHRAE Standard)

• Suits all structures; steel stud, block, concrete

• Extremely versatile grid can support large format panels 3200mm. x 1440mm.

• Traditional installation practices, no training needed

• Made in America

GRIDWORX is committed to providing contemporary construction techniques combined with current modern day materials that make the Gridworx system the best stone installation method in the world.

TopAnchor.dwg

TopAnchor.dwg TopAnchor.pdf

TopAnchor.pdf