The Gridworx Cladding System

The Gridworx cladding system is divided into four primary mounting configurations. Though each system is uniquely suited for it’s cladding material, they share many common components that can be utilized together to achieve a variety of unique architectural design aspects.

Gridworx is a Mechanically Attached Ventilated Backdrop Rainscreen Cladding System. Our systems can be utilized to achieve an open or closed joint aesthetic.

- An Open Joint rainscreen safely moderates pressure differences by allowing outside air to enter the pressure equalization chamber (PEC) behind the face of cladding. Open ventilation allows water and condensation to freely escape and evaporate from within the wall cavity.

- A Sealed Joint rainscreen is the traditional, straightforward strategy of rain control. Sealed joints form a watertight envelope around the building structure that significantly reduces water from entering the cavity. Weep holes within the Gridworx anchor and at the base of the wall allow excess moisture that penetrates the envelope to escape.

Common components that comprise the Gridworx cladding system includes:

- Starter J Course Anchor (12ft) in length. Used at the base of floor lines and above windows and doors.

- Intermediate T Anchor (12ft in Length). Used in the central field course.

- Top Course J Anchor (12ft length). Used at the top panel course and below windows and other architectural features.

- L-Brackets. The Gridworx proprietary method of engaging the panel with the anchor. Allows for the nonsequential removal and installation of panel. Available in 1/4″, 3/8”, 1/2″ and 3/4″ joints.

- Thermally broken adjustable wall bracket system. Designed to house exterior installation and create an adjustable, thermally broken structural backup between the Gridworx anchor and the substrate

GRIDWORX is committed to providing contemporary construction techniques combined with current modern day materials that make the Gridworx system the best stone installation method in the world.

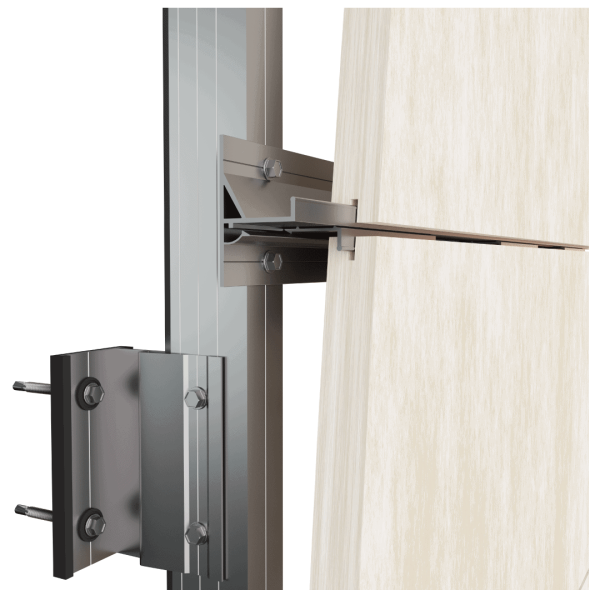

SKR (Saw Kerf Rotational)

Natural Stone

The original patented Gridworx system, designed to provide continuous panel support via saw kerfs cut into the top and bottom edge of the cladding. The L-bracket engagement method allows for non-sequential panel installation and the removal of damaged or discolored panels. This system pairs perfectly with any natural stone from our collection, cut to architectural specification and delivered to your jobsite.

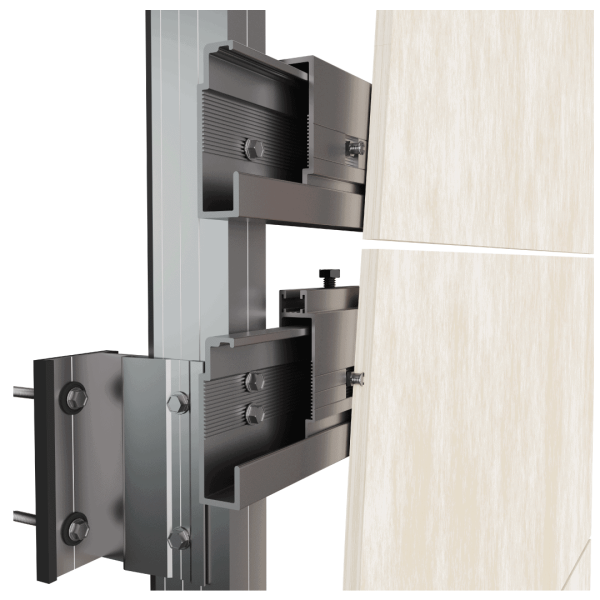

UKR (Undercut Kerf Rotational)

Multipurpose

A patented Gridworx system, the UKR (Undercut Kerf Rotational) channel interlocks with the back face of cladding via an undercut anchor. This connection between the UKR (Undercut Kerf Rotational) and stone provides superior load carrying capacity and adjustability. The L-bracket engagement method allows for non-sequential panel installation and the removal of broken or discolored panels.

CKR (Chemical Kerf Rotational)

Ultra-Compact Surface

The patented CKR (Chemical Kerf Rotational) is designed to provide continuous panel support via a 3mm kerf cut continuously along the top and bottom edge of the cladding panel. The black anodized Gridworx saddle locks into the 3mm kerf and is mechanically adhered to the back face of the panel, creating a modern aesthetic. The CKR product is available in 40+ colors, is panel heights up to 28” with lengths up to 126”.

UXF (Undercut XLarge Floating)

EXTRA Large Format Ultra-Compact Surface (UCS)

The Gridworx UXF system allows for the efficient installation of large format ultra-compact surface panels. Continuous rail anchors are fastened to the back face of panel in parallel rows, via an undercut anchor. These rails interlock with adjacent anchors attached to the substrate. Designed as a “floating mount system”, pitch bolts at the top channel allow for fast, pinpoint leveling.

CPH (Chemical Panel Handset)

Gridworx’s Chemical Panel Handset system (CPH) presents a compelling alternative to traditional mechanical cladding systems. It offers cost-effective advantages by simplifying the installation process, reducing the number of components required, and minimizing labor and materials. The system’s adjustable subframe allows for precise plumb alignment, ensuring an accurate and aesthetically pleasing finish.