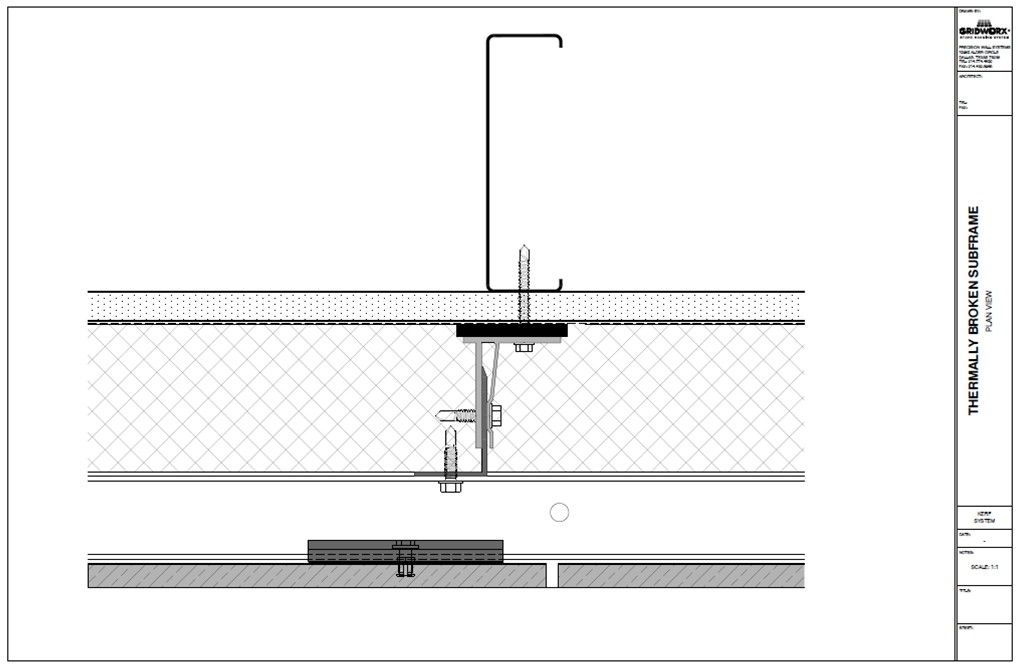

Undercut Kerf Rotational

Continuous dead-load support for each panel

6005A aluminum alloy T6 temper

75% minimum recycled content

Panel thickness range: 8mm – 2”

About the system

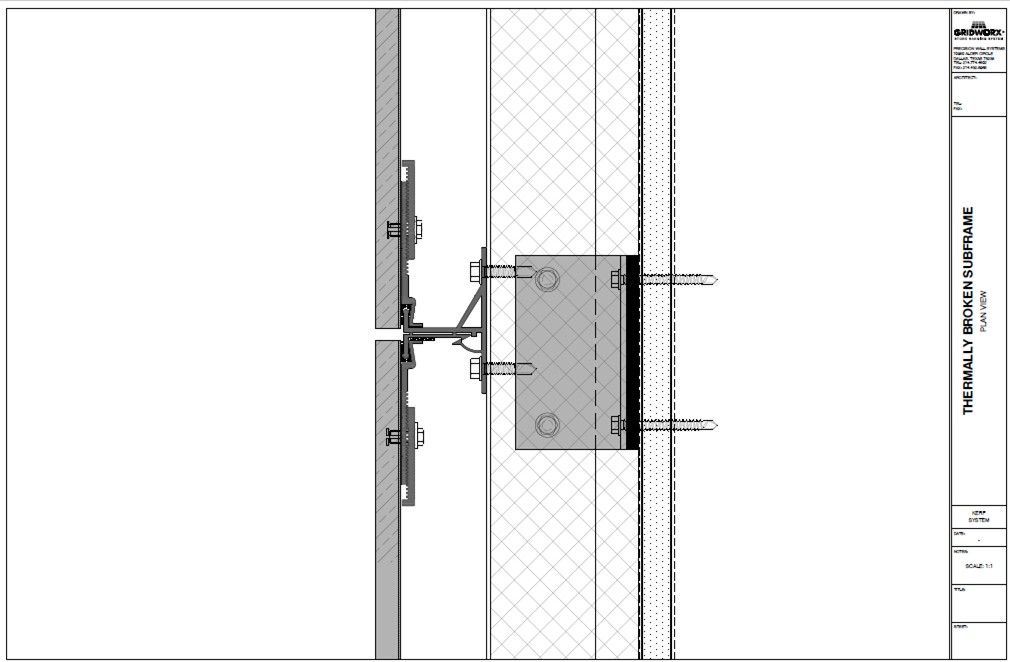

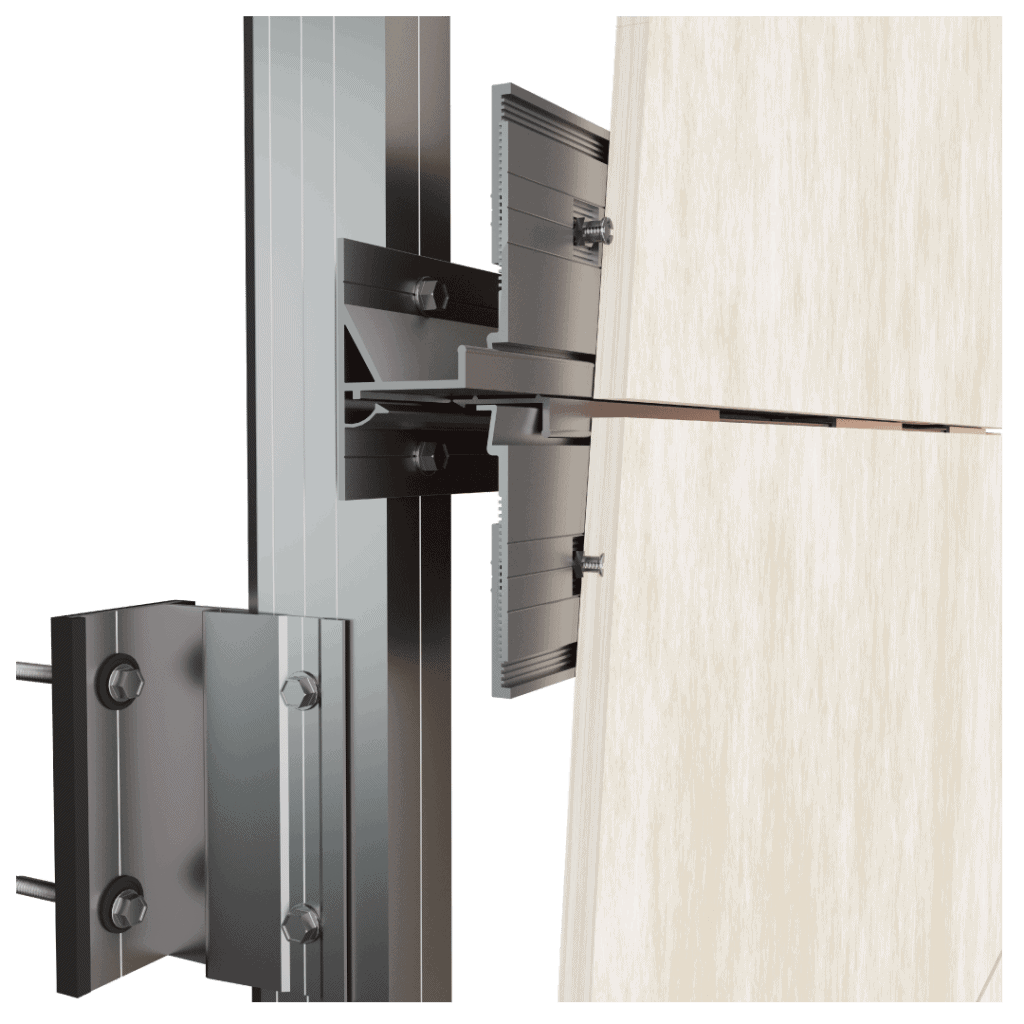

- Patented 2 part rotational engagement system using Undercut Anchor attachment

- Utilizes 4” long, discrete mechanical kerf extrusions that are applied via blind undercut anchors along the back surface, located along the top and bottom edge of the panel.

- Ideal panel height are between 12” to 36” or more (subject to engineering review)

Advantages include:

- Allows for precise multi-directional adjustments, including lateral, vertical, and horizontal positioning

- Perfect solution for Soffits, Underhangs, and Fascia Panels

- Same benefits of SKR (saw kerf rotational) system available for much thinner panels

- Allows for a fast and efficient installation

- Allows for Non-sequential installation of panels

- Easy removal/replacement of panels without affecting surrounding cladding

- Manageable panel sizes help to reduce labor expenses

Plan

Section